To effectively improve the situations above for a better user experience, it is necessary to fit the shock absorber between the capsule and the handle for a quality microphone.

When the user holds a microphone, speaking or singing, the turning and shaking gestures easily vibrate the microphone. Since it’s a rigid joint between capsule and handle, the vibrations directly transmit to capsule and thus results to inevitable noise and further affects the sound quality.

Some microphones are designed with switches. The motion of turning on/off leads to noise coming out due to the vibration.

Bad habits of using microphones like violently shaking and tapping, or even make it fall to the ground will not only produce unpleasant noise but also might damage the capsule and the microphone.

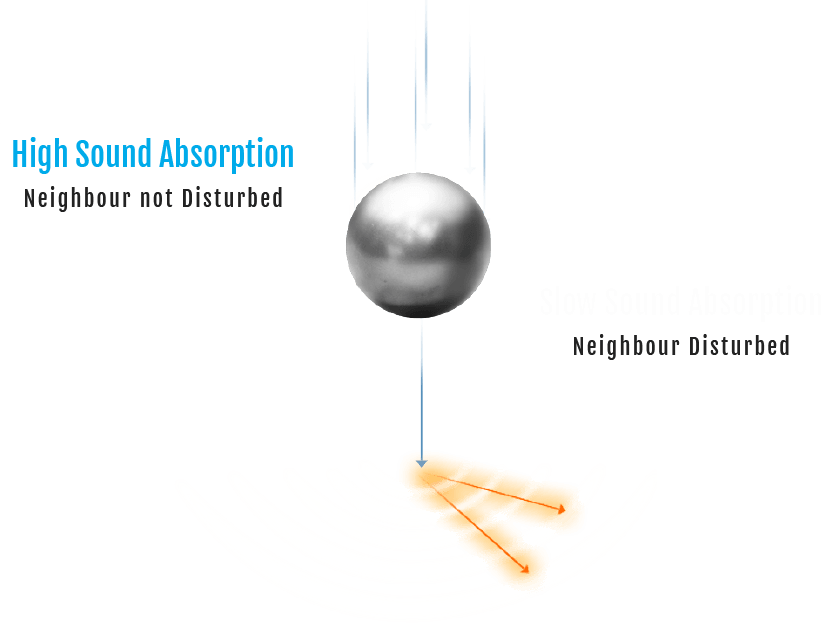

To reduce the noise, the shock absorbing materials are put between the capsule and the handle to help decrease the vibration. The unwanted noise is thus effectively reduced.

By adding rubber materials to absorb vibrations to reach shock absorbing effect.

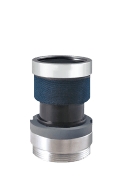

The shock absorber is made of vibration absorbing material Fit the capsule into the shock absorber,and then glue around the shock absorber and fix it onto the handle.